Markets Served

Electronics

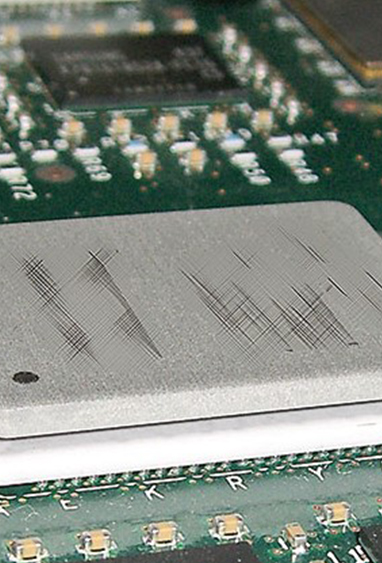

Electrical components requiring high resistivity mounting substrates that exhibit matched expansion coefficients and high voltage breakdown strengths are also perfect candidates for the use of high thermal conductivity Beryllium Oxide. Many cutting-edge medical tools leverage the computing power of advanced microprocessors. These include lasers, ultrasound equipment and digital imaging technologies. However, these devices are constantly challenged by increasingly greater amounts of waste heat, particularly as the demand increases for smaller sized instruments. Thus, as higher capabilities are designed into smaller instruments, waste heat must be safely managed and dissipated to prevent equipment inaccuracies or malfunctions.

Active thermal management generally includes pumped liquid cooling, refrigeration, and, most commonly, forced convection or fan-cooled technologies. Liquid cooling can manage high heat fluxes and provide remote heat dissipation. Refrigeration systems have adjustable cooling rates and can lower temperatures below ambient. Variable speed fans allow for adjustable cooling rates.

However, active cooling technologies have their own requirements. They need power, occasional replacement parts, and typically a control system. Refrigerators generate more heat than they remove, so the heat they generate must also be dissipated. This means energy requirements, parts and performance maintenance, and added space. Passive thermal management has fewer parts and no power requirements. A passive design can solve complex cooling problems in small spaces by minimizing the required airflow. Passive methods include heat sinks, heat pipe assemblies, vapor chamber assemblies, phase change materials, and highly thermally conductive materials such as Beryllium Oxide and Diamond.

At the component level, heat pipes can transfer high heat loads in small spaces and reduce the size of heat sinks. Heat pipes, often used in these applications, offer the advantages of two-phase passive cooling (working fluid evaporation and condensation cycle) with no moving parts, and can operate in any orientation.

More recently, heat pipes are being employed with fans in active cooling systems that can provide cooling to large packaging areas.

Heat pipes offer the advantages of two-phase passive cooling (working fluid evaporation and condensation cycle) with no moving parts, operate better against gravity, and are freeze thaw tolerant.

Vapor chambers are planar or flat versions of heat pipes. They include an evacuated vessel with a small amount of fluid inside and a capillary wick structure that lines the internal surfaces. Vapor chambers offer excellent heat spreading ability in all directions, allowing them to handle high heat fluxes and rapid thermal cycling. Vapor chambers can be designed to be less than 1 mm thick. For some applications, they can be matched to the coefficient of thermal expansion (CTE) for direct die attachment to the electronics, making this technology especially valuable for medical devices that require compact configurations.